In an unassuming neighborhood outside of Boston Massachusetts, there is a small park in the National Park System that documents the start of America’s industry, the Saugus Iron Works National Historic Site.

One of the reasons I like having a National Park Passport is that it gets me to places in the National Park System that I would not otherwise have heard of like the Saugus Iron Works which is the birthplace of the iron and steel industry in the United States.

History

The Puritans had a problem. They left England to form the Massachusetts Bay Colony in Boston because of religious differences with the rest of their countrymen. Their dream was to forge a colony that was self-sufficient, but forging was part of their problem. They were reliant on the mother country for all iron and steel and all the tools, plows, hammers and nails made from those materials.

In 1646, John Winthrop the Younger, the son of the founding governor, created a local ironworks to try and remedy that problem. They had a natural, if not great, source of iron in the nearby bogs. They had water power. But how do you turn water power into iron?

The Process

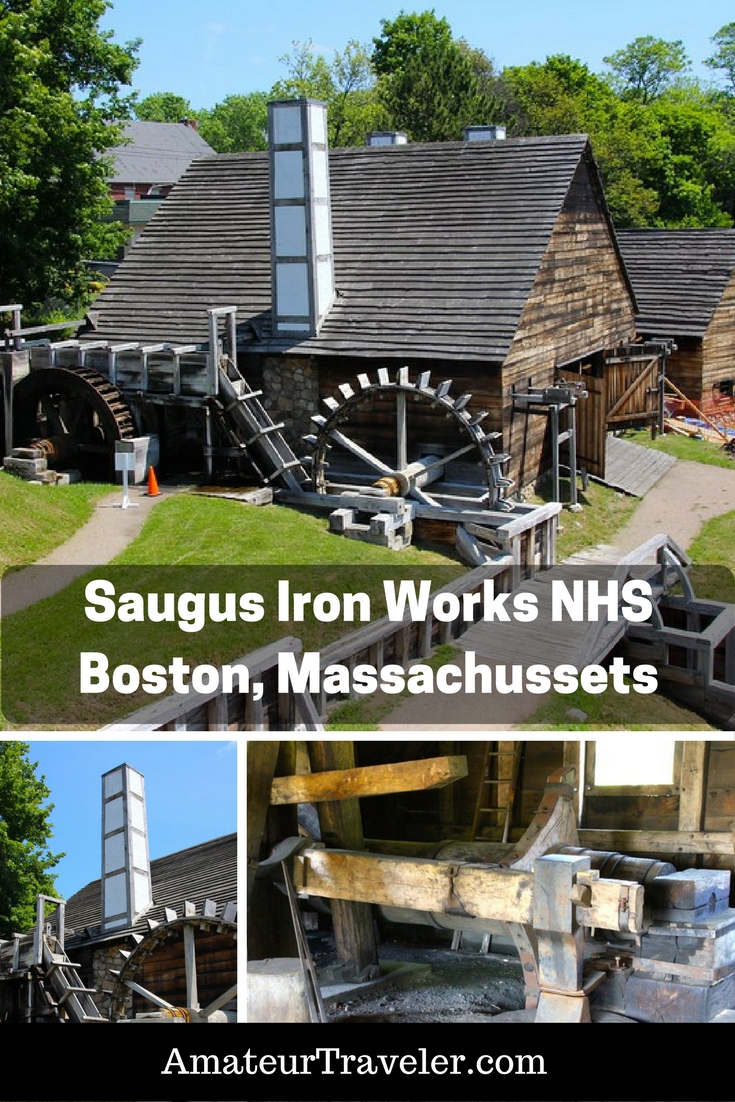

Saugus Iron Works was located on the Saugus River in what is now Lynn, Massachusetts. They dammed up the river and created watercourses to drive waterwheels.

1 – The Blast Furnace

In the blast furnace building, the large water wheel turned a shaft that drove two large bellows. The bellows drove air into the furnace to heat it up hot enough to melt rock. Into the top of the furnace, they dumped charcoal made from the local forests, bog iron, and rock called gabbro. The gabbro had been found locally and through trial and error, they learned that it helped remove the impurities from the iron.

The furnace, once lit, would burn for days. Twice a day they would open the bottom of the furnace and pour out the molten iron into bars of pig iron or into molds for cast iron implements.

2 – Cast Iron to Wrought Iron

To turn the brittle cast iron into the wrought iron needed for tools, they would repeatedly heat it up and pound it with hammers. In a second building, a large water wheel drove a massive hammer that would provide the needed force.

3 – Wrought Iron to Nails

Often the ironworks would just sell the wrought iron in bars that blacksmiths could use to create tools. They also cut the iron bars into long skinny strips for nails in a third building, again driven by water power. These nail rods would then be delivered to blacksmiths who would turn out nails one at a time in a very manual fashion.

The technology of the Saugus Iron Works was state of the art in the 1600s, especially the step that created nail blanks. Skilled ironworkers had to be hired from Europe as well as gangs of manual laborers and Scottish prisoners of war who would chop down the wood needed for charcoal production or do more of the manual tasks.

Problems

Some of the issues that the ironworks ran into were that those much-needed laborers were definitely not Puritans and they clashed with the laws of this very conservative community.

The bigger problem with the ironworks was that it didn’t make money. Eventually, the investors in England pulled the plug and the site was left to decay until it faded into the landscape.

As the workers left they spread out in the colonies and many of them took what they learned at Saugus to create their own ironworks.

- Log your park visits with a Passport To Your National Parks

- Get a Car Rental

- Buy Travel Insurance

- Book Your Accommodation HERE

- Search for Great Tours HERE

Rebirth

What you see today is a re-creation based on careful excavation in the 1940s and 1950s. The site was originally run by the American Iron and Steel Institute and was later given to the National Park Service.

Reading about the history of iron making might be interesting to history buffs like me, but when you visit the site you see, barring renovation and repair, functioning water wheels and machinery which is much more interesting. During my recent visit, the big hammer was silent as that waterwheel and shaft need to be replaced.

The site only takes an hour or two to visit. Time your visit for one of the informative talks by the local rangers.

more photos from Saugus Iron Works National Historic Site

+Chris Christensen | @chris2x | facebook

Leave a Reply

Tags: article, boston, massachusetts, national park, saugus iron works, video travel podcast

6 National Parks in Massachusetts Near Boston Worth Seeing

6 National Parks in Massachusetts Near Boston Worth Seeing Minuteman Missile National Historic Site – A Flashback to the Cold War

Minuteman Missile National Historic Site – A Flashback to the Cold War Manzanar National Historic Site – Ghosts of WWII in the California Desert

Manzanar National Historic Site – Ghosts of WWII in the California Desert Bent’s Old Fort National Historic Site – La Junta, Colorado

Bent’s Old Fort National Historic Site – La Junta, Colorado